English

English שפה עברית

שפה עברית  Kurdî

Kurdî  Español

Español  Português

Português  русский

русский  tiếng Việt

tiếng Việt  ภาษาไทย

ภาษาไทย  Malay

Malay  Türkçe

Türkçe  العربية

العربية  فارسی

فارسی  Burmese

Burmese  Français

Français  日本語

日本語  Deutsch

Deutsch  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Gaeilge

Gaeilge  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

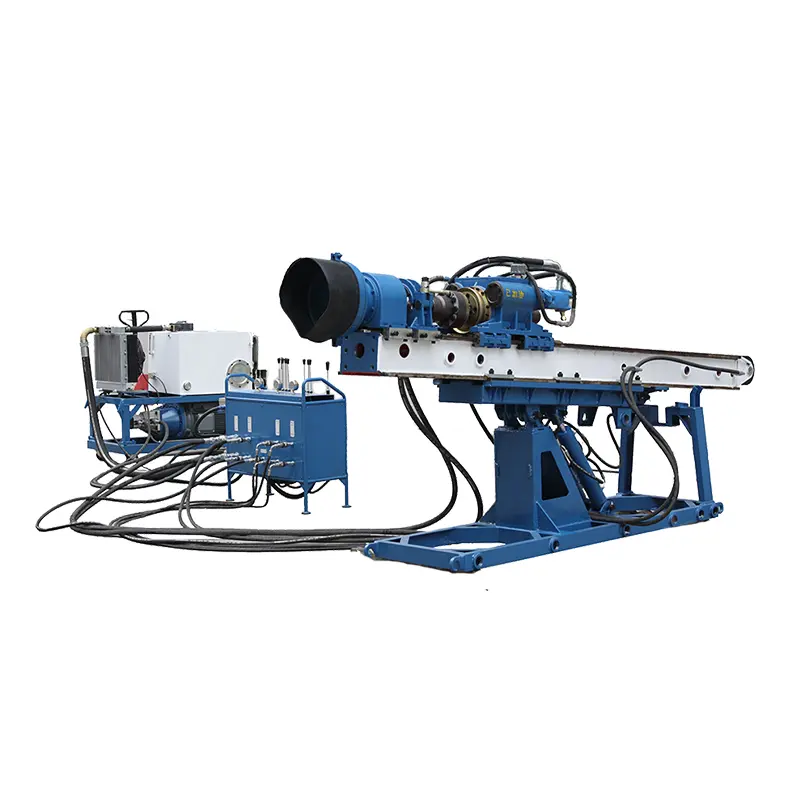

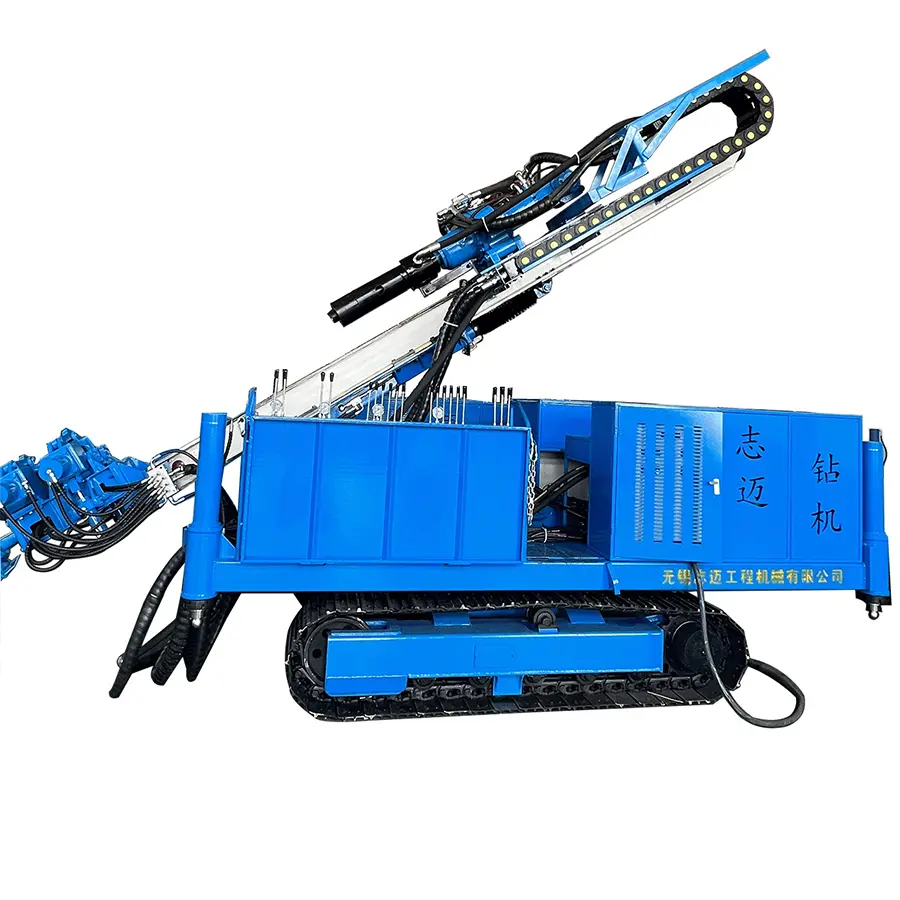

Underground Mining Drilling Rig

Send Inquiry

RM-320 can be used in mine and tunnel construction. Pipe support is a kind of advanced support technology in tunnel construction. It uses the excavated and erected steel arch frame as a fulcrum. Within a certain angle range outside the top contour line of the excavated cave, several steel pipes are driven into the face stratum, and pressure grouting is carried out into the stratum through the plum blossom-shaped grouting holes to reinforce the weak and broken stratum. It is a measure to support and reinforce the stratum in advance.

In engineering construction, drilling technology is the factor that has the greatest impact on engineering costs and construction period. Choosing a reasonable drilling technology according to the specific engineering geological conditions is an effective means to ensure the economic benefits of the project. The drilling rig can realize a variety of drilling processes by matching different working devices, thereby realizing one machine for multiple uses, which also greatly expands the application field of the drilling rig.

You can rest assured to buy underground mining drill rigs from our factory, we will provide you with the best after-sales service and timely delivery.

Main Technique Specifications:

| Description | Unit | Data | ||

| Engine | Model |

|

SC9DF330(II/IV) | |

| Rated power/speed | kW | 241/(2200r/min) | ||

| Rotary head (HB-500C) | low operation | Max.Torque | N.m | 19000-22000 |

| Rotate speed | r/min | 47 | ||

| fast operation | Max.Torque | N.m | 9500-11000 | |

| Rotate speed | r/min | 94 | ||

| Max.speed | r/min | 155 | ||

| Impact frequency | bpm | 1200-1500/1800-2300 | ||

| Impact force | N.m | 950-1200 | ||

| Hydraulic system | Main pump Max.pull-down piston push | Mpa | 28 | |

| Main pump | L/min | 180+180 | ||

| Auxiliary pump | L/min | 20+16 | ||

| Hydraulic oil tank capacity | L | 400 | ||

| Winch | Line pull(1st layer) | kN | 10 | |

| Maximum rope speed | m/min | 30 | ||

| Rope diameter | mm | 12 | ||

| Rope capacity | m | 40 | ||

| Description | Unit | Data | |

| Hoist&Feed system | Feed type |

|

Motor/Hydrauicyinder+chain |

| Feed stroke | mm | 4800 | |

| Maximum hoist pull speed | m/min | 29 | |

| Maximum feed speed | m/min | 58 | |

| Thrust/uplift force | KN | 55/127 | |

| Undercarriage | Travelling speed | km/h | 3 |

| Max.climbable gradient of the overall unit |

|

26.5 | |

| Track shoe width | mm | 450 | |

| Over allwidth | mm | 2240 | |

| Overallength | mm | 3280 | |

| Average ground pressure | kPa | 70 | |

| Clamps | Nominal size | mm | 60-300 |

| Maximum Clamping force | KN | 350 | |

| Maximum breaking torque | KN ·m | 50 | |

| Construction parameters | Max.parallel height | mm | 4000 |

| Max.borehole diameter | mm | 300 | |

| Max.drilling depth | m | 150 | |

| Dimension in transport condition(L×W×H) | mm | 8200*2260*2700 | |

| Weight of overall unit(standard configuration) | Kg | 14500 | |