English

English שפה עברית

שפה עברית  Kurdî

Kurdî  Español

Español  Português

Português  русский

русский  tiếng Việt

tiếng Việt  ภาษาไทย

ภาษาไทย  Malay

Malay  Türkçe

Türkçe  العربية

العربية  فارسی

فارسی  Burmese

Burmese  Français

Français  日本語

日本語  Deutsch

Deutsch  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Gaeilge

Gaeilge  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

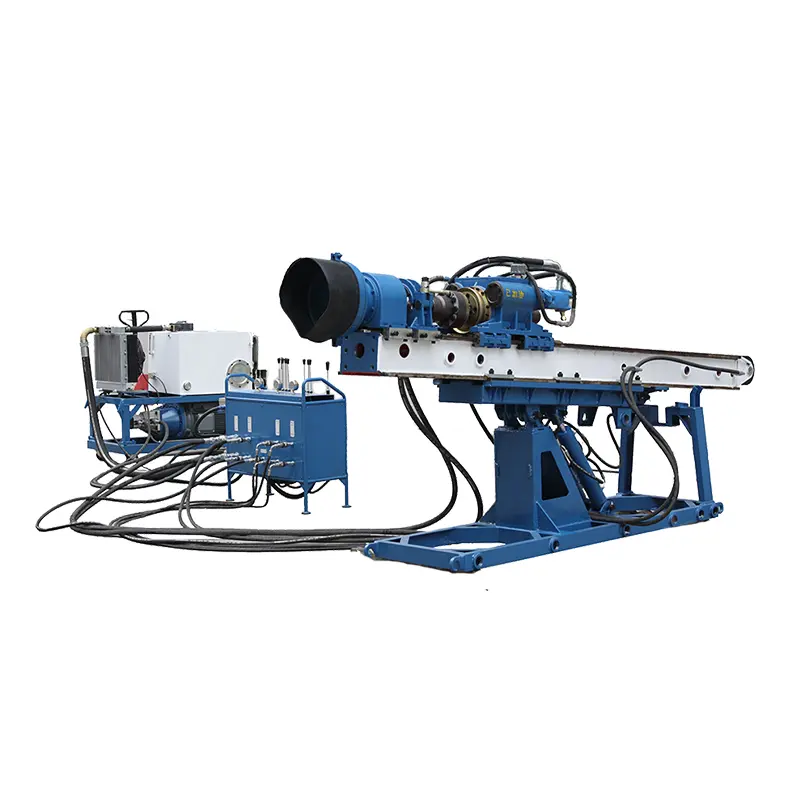

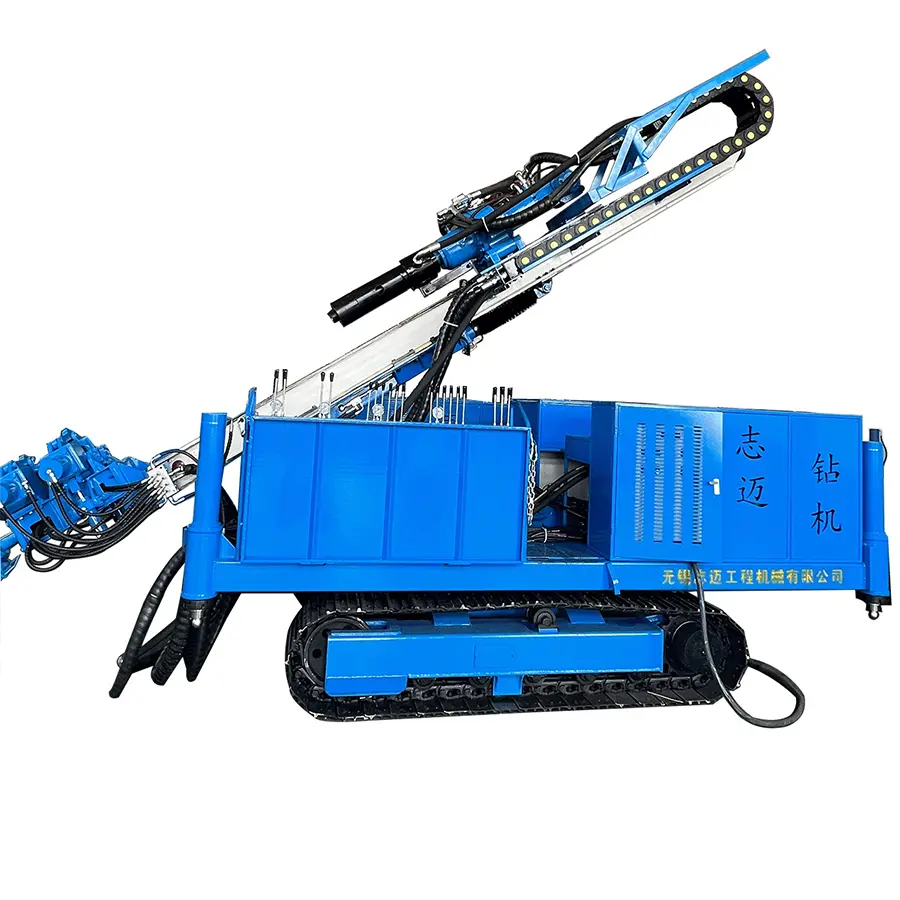

Crawler Anchor Drilling Rig

Send Inquiry

ZDL-135D is a high-efficiency drill rig developed by RM based on domestic subways, high-rise buildings, airports, ground source heat pumps and other deep foundation pits for anchoring, jet grouting, and water lock. The drill rig is integral and equipped with a crawler walking chassis and a clamping shackle. The root canal drilling tool can be used to drill holes with the casing, and the lifting and jet grouting functions are added.

You can rest assured to buy crawler anchor drill rigs from our factory, and every request of yours will be answered within 24 hours. If you are interested in crawler anchor drill rig products, please contact us.

Crawler anchor drilling rig machine introduction

Cover: The added cover makes the machine appearance more scientific and protects the key hydraulic parts from pollution;

Legs: Not only does it prevent the oil cylinder from damage, but it also enhances the support strength;

Operation table: The split operation table makes the operation simpler and avoids misoperation;

Crawler: Longer and stronger crawler effectively prevents sinking and adapts to a wider range of strata;

Lifting: The hole height can be adjusted and no longer depends on the height of the working surface;

Automatic turntable: It eliminates manual labor and is easier and more convenient;

Power head: The drilling rig slewing device is driven by dual hydraulic motors, with large output torque and a lower center of rotation than similar products, which greatly improves the balance of the drilling rig cobalt hole. The configured expansion joint can greatly extend the thread life of the cobalt rod;

Large through-hole high-pressure faucet: A necessary device for enlarged head construction;

Cooling system: The cooling system is optimized for the special working conditions of the customer's local area to ensure that the maximum temperature of the hydraulic system does not exceed 70℃ when the outdoor temperature is 45℃.

Construction features

● Optional special pipe drilling tools (drill rod, casing, eccentric cobalt head), casing wall protection for opening holes in unstable formations, and conventional ball-tooth drill bits for final drilling. High drilling efficiency and good hole quality.

● Crawler anchor drilling rigs are mainly used for anchor support of deep foundation pits. The drilling rig can also be used for rotary grouting construction by replacing the rotary grouting module. In addition, this machine also has strong performance in the construction of geothermal holes, precipitation wells, micro steel pipe piles and micro cast-in-place piles.

● In addition to the crawler chassis, clamping shackle and turntable, the crawler anchor drilling rig also provides users with optional accessories such as rotary grouting modules. Users can select and superimpose them when ordering the drilling rig to make our drilling rig more suitable for your project.

Basic performance and parameters

| Basic parameters | |

| Drilling diameter: | Φ150-Φ250(mm) |

| Drilling depth: | 100-140(m) |

| Drill pipe diameter/casing diameter: | Φ89/Φ102/Φ114/Φ127/Φ133/Φ140/Φ146/Φ168(mm) |

| Drilling inclination: | 0-90(°) |

| Boom lifting height: | 447(mm) |

| Rotator output speed: | 10/20/25/40/50/60/70/100/120/140(r/min) |

| Rotator output torque: | 6800(N. m) |

| Rotator travel: | 3400(mm) |

| Propel rack feeding process: | 3400(mm) |

| Rotator lifting force: | 65(KN) |

| Rotator lifting speed: |

0-2. 8 Adjustable/7/18/25(m/min) |

| Rotator pressure: | 33(KN) |

| Rotator pressurizing speed: | 0-1. 4 Adjustable/14/36/50(m/min) |

| Walking parameters | |

| Walking style: | Track walking |

| Climbing angle: | 25° |

| Track ground pressure: | 40kpa |

| Walking speed: | 0. 4KM/h |

| Rotation parameters | |

| Rotation method: | Automatic rotation of the whole machine |

| Rotating structure: | Slewing bearing |

| Positioning method: | Positioning pin |

| Input power | |

| Input power (motor): | 55+18. 5(KW) |

| Shipping status(L*W*H): | 5400*2100*2200(mm) |

| Weight: | 6500(kg) |