English

English שפה עברית

שפה עברית  Kurdî

Kurdî  Español

Español  Português

Português  русский

русский  tiếng Việt

tiếng Việt  ภาษาไทย

ภาษาไทย  Malay

Malay  Türkçe

Türkçe  العربية

العربية  فارسی

فارسی  Burmese

Burmese  Français

Français  日本語

日本語  Deutsch

Deutsch  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Gaeilge

Gaeilge  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

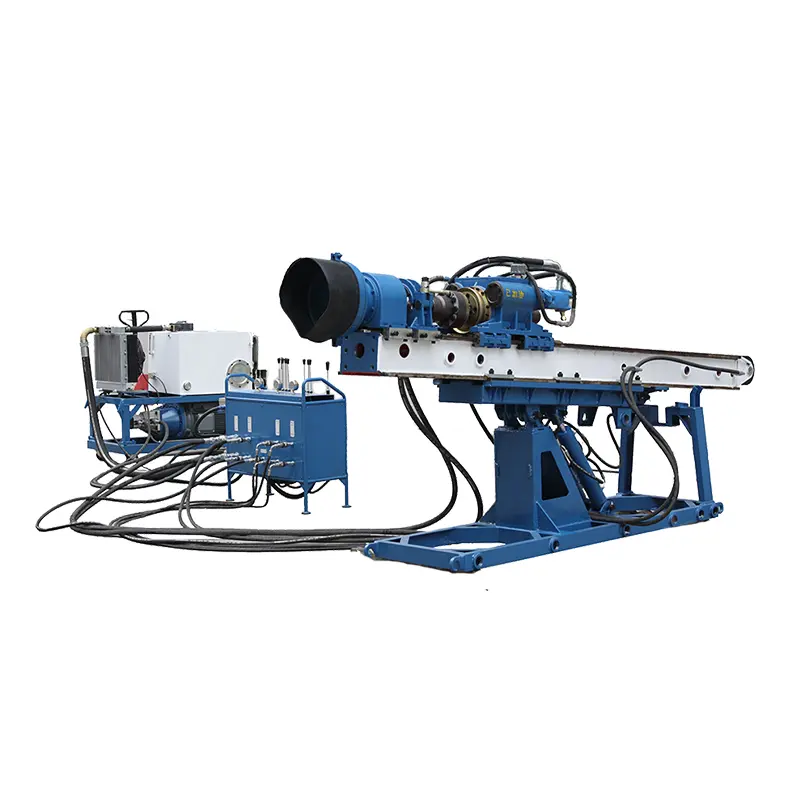

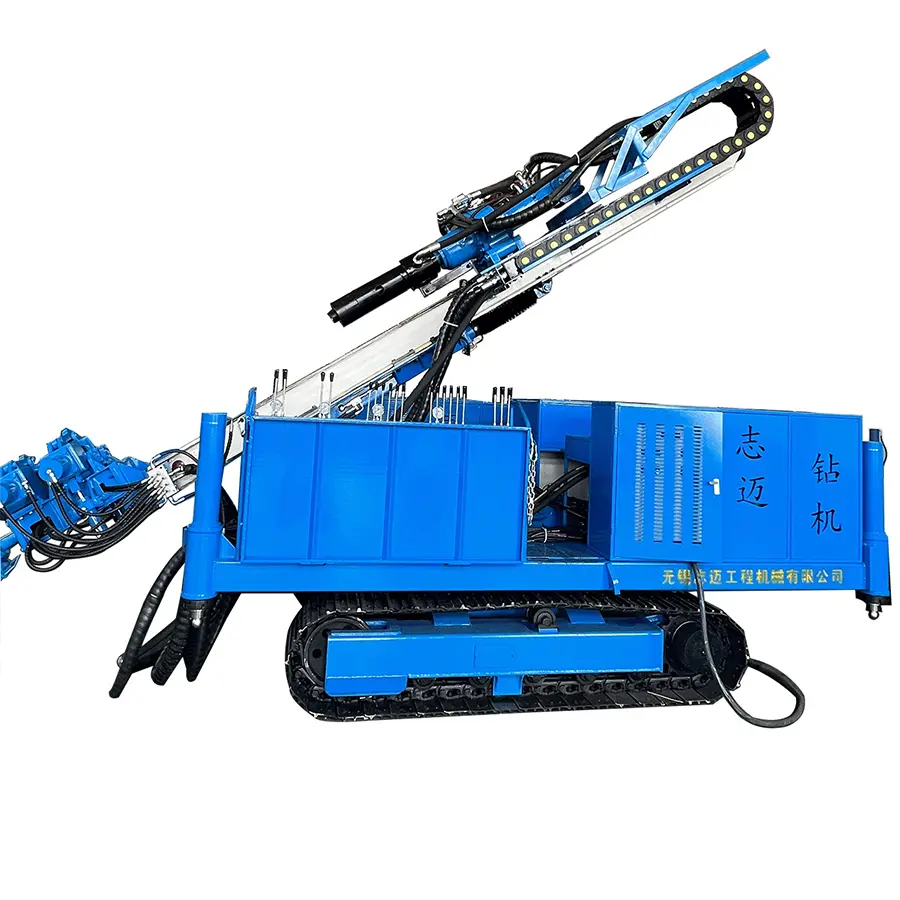

Rock Drilling Rig

Send Inquiry

ZDL-150F is a high-efficiency drilling rig developed by RM for anchoring, jet grouting and water-locking in domestic subways, high-rise buildings, airports, ground source heat pumps and other deep foundation pits. The drilling rig is integral and equipped with a crawler chassis and a clamping shackle. The root canal drilling tool can be used to drill holes with the casing, and free rotation and jet grouting functions are added.

Welcome to buy rock drilling rigs from us. Every request from customers will be responded to within 24 hours.

Machine introduction

● Torque and speed can be reasonably matched according to actual needs. The propulsion frame has a stroke of 3.4 meters, which can be used for composite drilling of 3-meter drill rods and casings. The rotator with corresponding torque can be configured according to different formations, which improves the adaptability of the drilling rig.

● The rock drilling rig is equipped with a crawler chassis, a high-position rotating platform, a large-diameter outrigger cylinder, a 0.9-meter slide, and a hole support device, which makes the displacement and positioning of the drilling rig extremely convenient, and it is stable and reliable during drilling.

● The rock drilling rig is equipped with a clamping shackle, which makes loading and unloading drill rods and casings low in labor intensity and high in efficiency.

Construction characteristics of rock drilling rig

● Three-wing cobalt head drilling, mud slag. Suitable for high-speed drilling in soil, sand and other strata; air down-the-hole hammer drilling, air slag, high configuration cost, air compressor above 15 cubic meters, submersible hammer, large pollution, suitable for rock and broken layer construction; bottom hole hydraulic hammer drilling, mud slag, low configuration cost, equipped with BW-320 pump, hydraulic hammer, less pollution, suitable for broken layer, sand and egg layer and other strata with high water content.

● Casing drilling; Drill rod and casing composite drilling; foundation pit dewatering; micro-cast piles; single, double, triple rotary spraying, fixed spraying, swing spraying and other rotary spraying processes.

● Geothermal hole (water well) construction and survey (equipped with winch module, orifice device module, can be used for survey and construction within 100 meters); static penetration (5T static penetration); dynamic penetration.

Basic performance and parameters

| Basic parameters | |

| Drilling depth: | Φ150-Φ250(mm) |

| Drilling depth: | 100-140(m) |

| Drill pipe diameter/casing diameter: | Φ89/Φ102/Φ114/Φ127/Φ133/Φ140/Φ146/Φ168(mm) |

| Drilling inclination: | 0-90(°) |

| Rotator output speed: | 10/20/25/35/40/50/70/100/120/140(r/min) |

| Rotator output torque: | 8000(N. m) |

| Rotator travel: | 3400(mm) |

| Propel rack feeding process: | 900(mm) |

| Rotator lifting force: | 75(KN) |

| Rotator lifting speed: | 0-1. 4 adjustable/7/18/26(m/min) |

| Rotator pressure: | 33(KN) |

| Rotator pressurizing speed: | 0-2. 8 adjustable/14/36/80(m/min) |

| Walking parameters | |

| Walking style: | Track walking |

| Climbing angle: | 25° |

| Track ground pressure: | 37. 8kpa |

| Walking speed: | 0. 4KM/h |

| Rotation parameters | |

| Rotation method: | Automatic rotation of the whole machine |

| Rotating structure: | Slewing bearing |

| Positioning method: | Positioning pin |

| Input power (motor): | 55+18. 5(KW) |

| Shipping status(L*W*H): | 5400*2100*2200(mm) |

| Weight: | 6500(kg) |