English

English שפה עברית

שפה עברית  Kurdî

Kurdî  Español

Español  Português

Português  русский

русский  tiếng Việt

tiếng Việt  ภาษาไทย

ภาษาไทย  Malay

Malay  Türkçe

Türkçe  العربية

العربية  فارسی

فارسی  Burmese

Burmese  Français

Français  日本語

日本語  Deutsch

Deutsch  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Gaeilge

Gaeilge  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

Elevated Jet Drilling Rig

Send Inquiry

The MDL-150D8 multi-function drilling rig is a new multi-function self-drilling rig developed by RM based on the existing MDL series drilling rigs, taking into account the construction sequence of foundation engineering jet grouting, anchoring, and anti-floating anchor rods.

You can rest assured to buy overhead jet grouting drilling rigs from our factory, and RM will provide you with the best after-sales service and timely delivery.

Main uses:

1. Soft foundation treatment

2. Water-stop curtain

3. Drilling hole construction

Main features of the elevated rotary jet drilling rig:

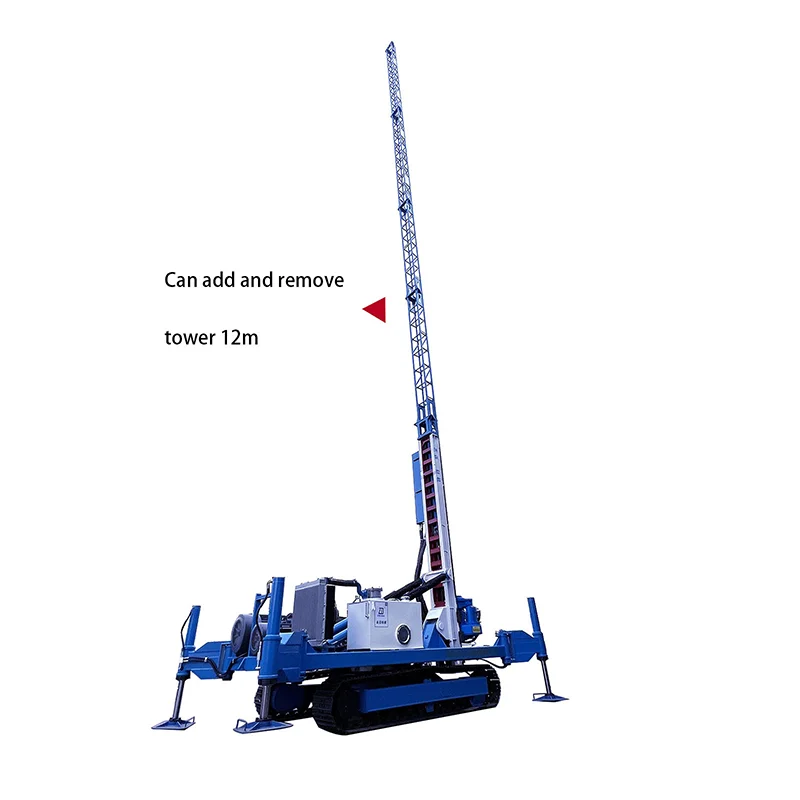

1. A detachable 12-meter auxiliary tower is installed

● During rotary jet construction, it can replace the elevated rotary jet, reduce the number of drill tool disassembly, save time and materials, and reduce quality risks.

● During the construction of anti-floating anchor rods, the anchor rods can be lifted, saving the cost of the crane.

● The detachable auxiliary tower can be disassembled during the construction of inclined anchor cables without affecting other functions of the drilling rig.

● During the construction of short anchor rods, one rod can be used to the end, saving time and effort.

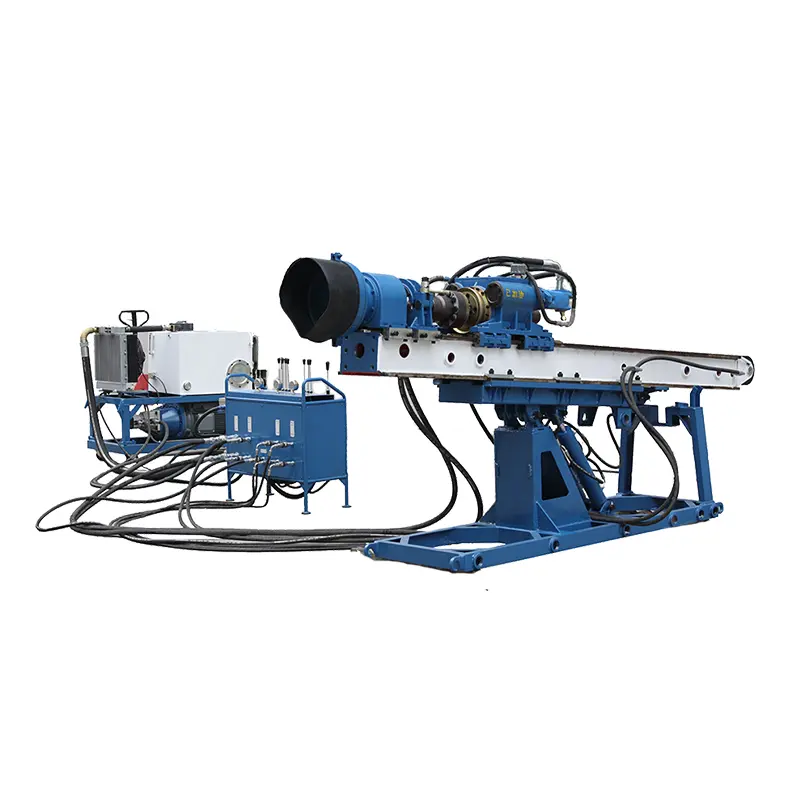

2. Large through-hole rotator

● The through-hole diameter is 92mm, and the 89 drill rod can pass smoothly. It can achieve triple rotary jet construction and anchoring construction.

● Ordinary 89 steel pipes can also be used for anchoring construction.

● The hydraulic chuck structure allows the replacement of drilling tools to be convenient and free. No need to worry about replacing transition joints.

●The high torque power head, combined with our enhanced jet grouting drill, can be used in most strata for jet grouting construction without the need for a pilot hole, saving a lot of cost and time.

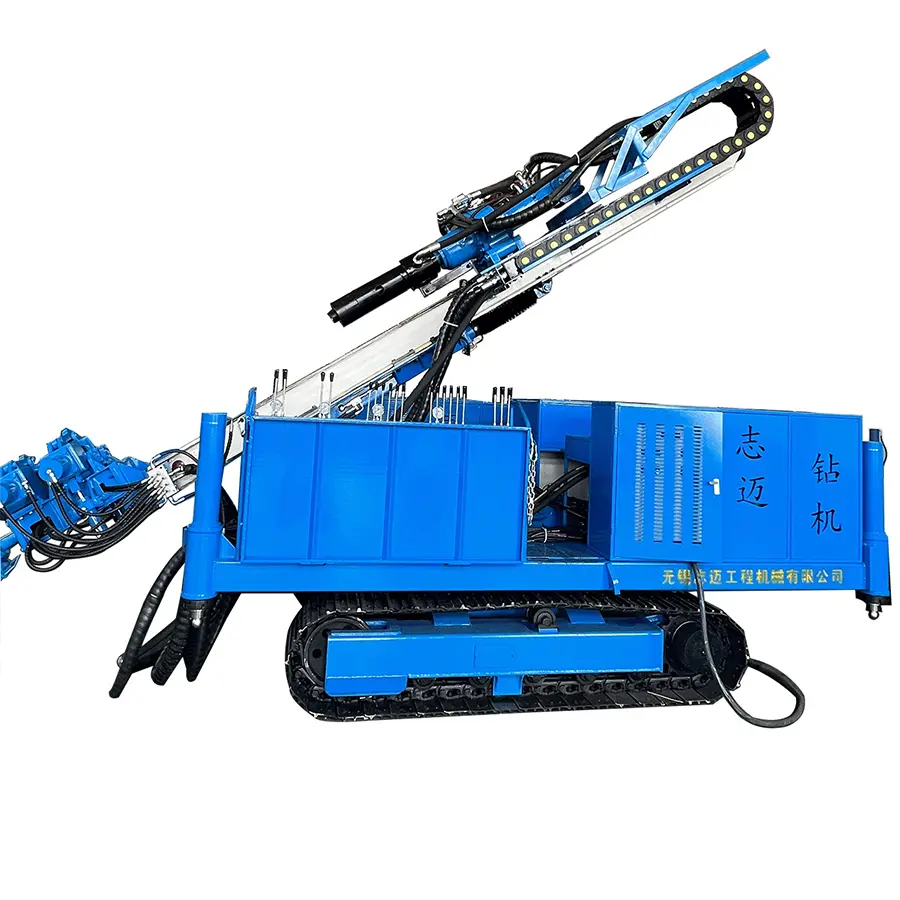

3. Track travel

The elevated jet grouting drill uses a track chassis with a large ground pressure ratio. It can move freely even on soft ground.

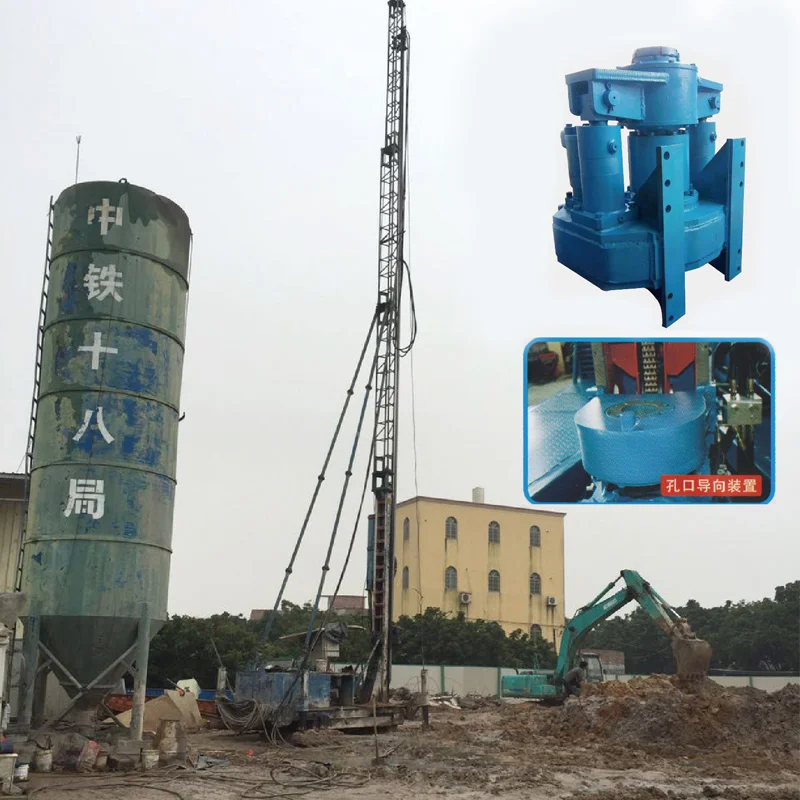

4. Orifice guide device

●During jet grouting construction, the drill can be easily disassembled, while achieving the construction angle and verticality.

●During anchor construction, the force of the steel pipe can be improved, and the construction accuracy is high.

●The rotation mechanism of the orifice can reduce the wear on the cobalt tool.

Main Technique Specifications:

| Specification: | MDL-150D8 |

| Hole depth (m): | 50-80 |

| Rod diameter (mm): | ф73, ф89 |

| Jet-grouting: | Single, double, triple |

| Stake diameter (mm): | 400~600, 600-1200, 800~1600 |

| Length of Joint pipe (m): | 16 |

| Hole angle(°): | 0-90 |

| Output speed of power head(r/min): | 10, 20, 30, 35, 40, 60, 70, 85, 130, 170 |

| Output torque of power head(N. m): | 10000 |

| Stroke of power head(mm): | 3400 |

| Stroke of slide flame(mm): | 900 |

| Lifting force of power head (KN): | 70 |

| Lifting speed of power head(m/min): | 0-5(adjustable)7/23/30 |

| Feeding force of power head(KN): | 36 |

| Feeding speed of power head(m/min): | 0- 10(adjustable)14/46/59 |

| Elevating power of winch (KN): | 15 |

| Input power(Electromotor)(KW): | 55+18. 5 |

| Dimension(L* W*H) (mm): | 5800*2100*2000 |

| Weight(kg): |

6500 |