English

English שפה עברית

שפה עברית  Kurdî

Kurdî  Español

Español  Português

Português  русский

русский  tiếng Việt

tiếng Việt  ภาษาไทย

ภาษาไทย  Malay

Malay  Türkçe

Türkçe  العربية

العربية  فارسی

فارسی  Burmese

Burmese  Français

Français  日本語

日本語  Deutsch

Deutsch  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Gaeilge

Gaeilge  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

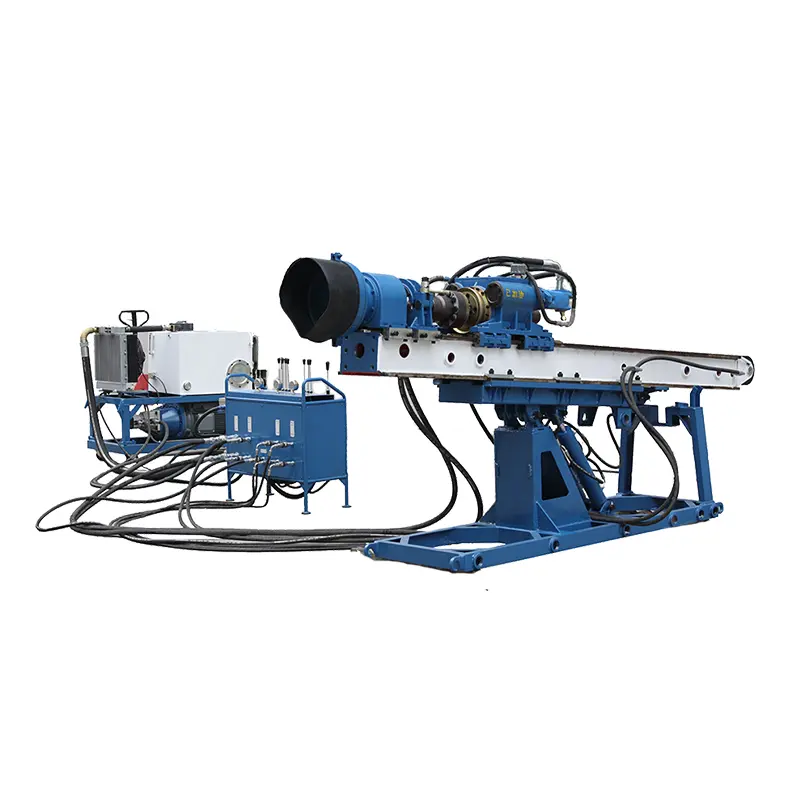

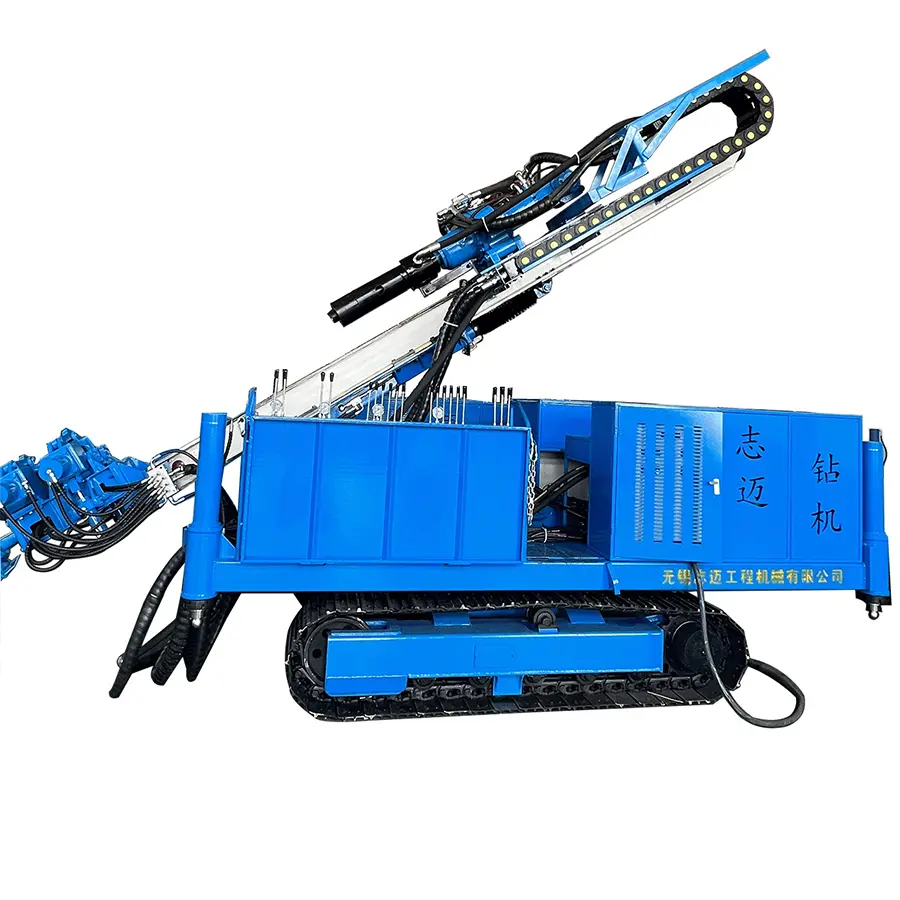

Crawler Type High Lift Anchor Drilling Rig

Send Inquiry

MDL-150H crawler high lift anchor drilling rig is a high-efficiency drilling rig developed by RM for anchoring, jet grouting and dewatering in subways, high-rise buildings, airports, ground source heat pumps and other deep foundation pits.

RM is a professional crawler high lift anchor drilling rig manufacturer and supplier in China. If you are interested in crawler high lift anchor drilling rig products, please contact us. We follow the principles of assured quality, conscientious price and enthusiastic service.

Main features:

1. The maximum speed of the crawler high-lift anchor drilling rig can reach 170 rpm; it has increased by 20% compared with the MDL-135H, and has considerable efficiency for twist drills and soil layers.

2. Energy saving and high efficiency: the work efficiency is effectively increased without increasing the power.

3. While the speed of the crawler high-lift anchor drilling rig increases, the torque increases by 10% compared with the MDL-135H, and the peak torque increases to 7500NM.

4. A new hydraulic system is adopted, with a simple structure, reasonable layout and humanized operation.

5. Compared with the MDL-135H drilling rig, the construction efficiency has increased by about 20%. The torque and speed can be reasonably matched according to actual needs. The propulsion frame stroke is 3.4 meters, and 3 meters of drill rod and casing composite drilling can be carried out.

The crawler high-lift anchor drilling rig can be equipped with a rotator with corresponding torque according to different formations, which increases the adaptability of the drilling rig. It is equipped with crawler chassis, high-position rotating platform, large-diameter outriggers, 0.9-meter slide, and hole support device, which makes the drilling rig easy to move and fix, and stable during drilling. It is equipped with a clamping shackle, which makes loading and unloading drill pipes and casings less labor-intensive and more efficient.

Common construction techniques:

1. Three-wing drill bit drilling, mud slag removal. Applicable to high-speed drilling in soil layers and other strata.

2. Air down-the-hole hammer drilling, air slag removal. Applicable to rock and broken layer construction.

3. Bottom-hole hydraulic hammer drilling, mud slag removal. Applicable to broken layers, sand and gravel layers and other strata with high water content.

4. Casing drilling.

5. Drill rod and casing composite drilling.

6. Single, double, triple rotary spraying, fixed spraying, swing spraying and other rotary spraying techniques.

Main Technique Specifications:

| Specification: | MDL-150D |

| Hole diameter (mm): | ф150-ф250 |

| Hole depth(m): | 130-170 |

| Rod diameter(mm): | ф73, ф89, ф102, ф114 |

| Hole angle(°): | -40-90 |

| Output speed of power head(r/min): | 10, 20, 30, 35, 40, 60, 70, 85, 130, 170 |

| Output torque of power head(N. m): | 7500 |

| Stroke of power head(mm): | 3400 |

| Stroke of slide flame(mm): | 900 |

| Lifting force of power head (KN): | 70 |

| Lifting speed of power head(m/min): | 0-5(adjustable)7/23/30 |

| Feeding force of power head(KN): | 36 |

| Feeding speed of power head(m/min): | 0-10(adjustable)14/46/59 |

| Input power(Electromotor)(KW): | 55+18. 5 |

| Dimension(L* W*H) (mm) | 5400*2100*2000 |

| Weight(kg) | 6500 |