English

English שפה עברית

שפה עברית  Kurdî

Kurdî  Español

Español  Português

Português  русский

русский  tiếng Việt

tiếng Việt  ภาษาไทย

ภาษาไทย  Malay

Malay  Türkçe

Türkçe  العربية

العربية  فارسی

فارسی  Burmese

Burmese  Français

Français  日本語

日本語  Deutsch

Deutsch  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Gaeilge

Gaeilge  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

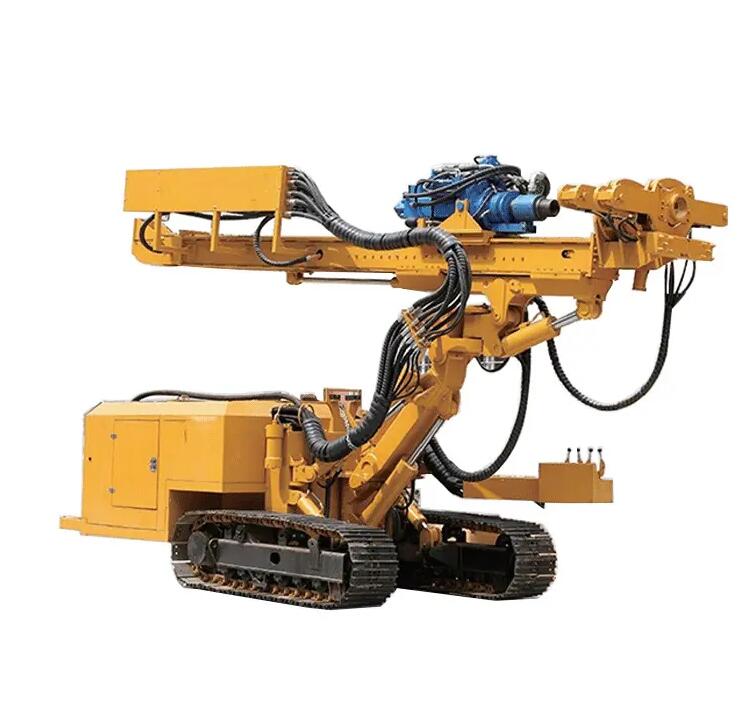

Operating Faults and Solutions for Multi Functional Anchoring Drilling Rig

2025-09-13

Operating Faults and Solutions for Multi Functional Anchoring Drilling Rig

Excessive Swinging During Drilling with the Multi Functional Anchoring Drilling Rig

Causes: Deformed or bent drill rod; worn chuck sleeve; worn air leg.

Solutions: Use qualified drill rods; check the chuck sleeve for wear and replace the spindle if worn.

Failure to Push and Install the Anchor Rod into Position

Causes: Insufficient manual thrust; misalignment between the drilling rig and the anchor hole; use of unsuitable resin cartridges or bent anchor rods.

Solutions: Increase manual thrust; align the Multi Functional Anchoring Drilling Rig with the anchor hole; check if the resin cartridges meet requirements and use qualified anchor rods.

Low Thrust from the Air Leg or Failure to Stabilize at the Set Point

Causes: Blocked air passage; leaking exhaust valve; damaged seals in the air leg.

Solutions: Check the air intake passage of the air leg to ensure smooth airflow; inspect the seals of the exhaust valve for damage and replace if necessary; check the seals of the air leg for wear and replace worn parts.

High Reaction Torque Felt on the Handle During Drilling

Causes: High air pressure, low water pressure; damaged drill bit; sudden increase in thrust during operation.

Solutions: Check if air and water pressure values are normal; inspect and replace damaged drill bits; improve operating methods to ensure smooth operation.

Slow Motor Rotation

Causes: Low air pressure; blockage or severe air leakage in the intake pipeline.

Solutions: Check air pressure, which should be 0.4–0.63 MPa; clear any blockages in the intake pipeline by blowing it clean, clean or replace the filter and screen, or replace the intake pipe.

Reduced Drilling Speed of the Multi Functional Anchoring Drilling Rig

Causes: Low air pressure; use of unsuitable drill bits; excessive wear of the drill bit; hard rock formation; low water pressure; severe wear of bearings or gears.

Solutions: Check air pressure and ensure it reaches a reasonable value; use appropriately matched drill bits; reduce rotation speed and increase air leg thrust; check water pressure, which should be 0.6–1.2 MPa.